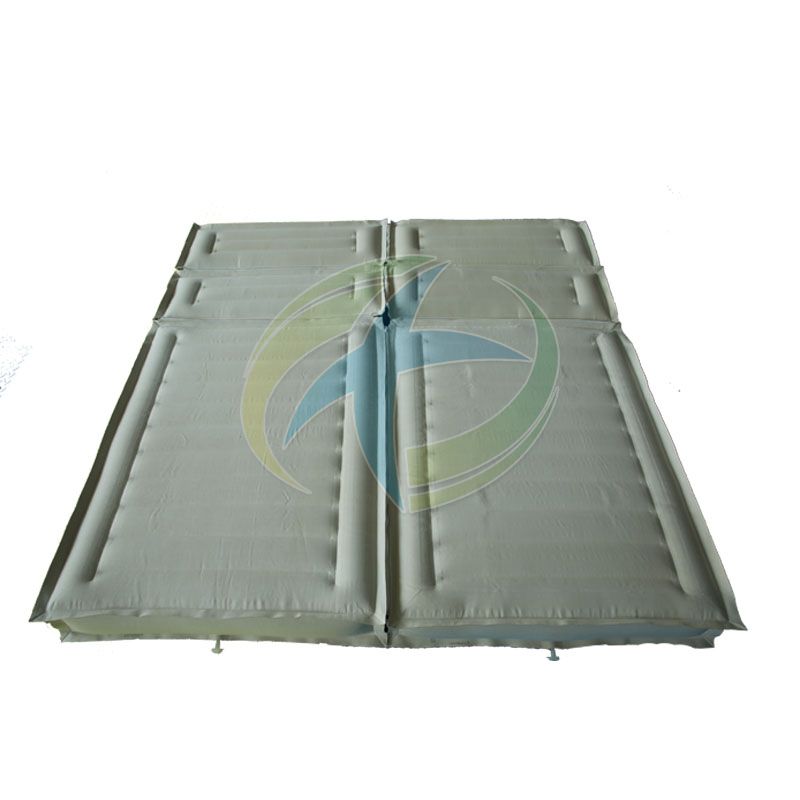

Vulcanized Rubber Air Chamber: Enhancing Performance and Safety

When it comes to achieving optimal performance and ensuring safety, Vulcanized Rubber Air Chambers have emerged as a game-changer in numerous industries. This innovative technology combines the superior durability of vulcanized rubber with the versatility and efficiency of air chambers. By seamlessly integrating the two, Vulcanized Rubber Air Chambers offer a wide range of applications, from automotive engineering to aerospace. In this article, we will explore the remarkable attributes of Vulcanized Rubber Air Chambers, their benefits, and their diverse use cases.

Benefits of Vulcanized Rubber Air Chambers:

Vulcanized Rubber Air Chambers offer a multitude of advantages over traditional materials. Firstly, the vulcanization process enhances the durability and resilience of the rubber, making it highly resistant to wear, tear, and impact. This translates into extended product lifespan and reduced maintenance costs. Additionally, the integration of air chambers allows for adjustable cushioning and shock absorption, offering enhanced safety and comfort.

Applications in Automotive Engineering:

In the automotive industry, Vulcanized Rubber Air Chambers find widespread use in various components. From suspension systems to engine mounts, these air chambers provide excellent vibration isolation, reducing noise and enhancing overall vehicle performance. Furthermore, their ability to adapt to changing road conditions improves handling and stability.

Utilization in Aerospace Industry:

Vulcanized Rubber Air Chambers play a crucial role in the aerospace sector, where lightweight yet robust materials are essential. These air chambers are employed in aircraft seating, offering superior comfort during long flights. Additionally, they contribute to the structural integrity of aircraft components, absorbing vibrations and ensuring passenger safety.

Enhancing Performance in Sports Equipment:

From running shoes to protective gear, Vulcanized Rubber Air Chambers are revolutionizing the sports industry. By providing optimal cushioning and shock absorption, these air chambers minimize the risk of injuries, enabling athletes to perform at their best. The customizable nature of the chambers allows for tailored support, catering to the unique needs of each sport.

Implementations in the Construction Sector:

The construction industry greatly benefits from Vulcanized Rubber Air Chambers, especially in areas such as building foundations and seismic isolation. These air chambers effectively mitigate vibrations caused by earthquakes or heavy machinery, protecting structures from damage. Additionally, they offer versatility in various applications, such as expansion joints and bridge bearings.

Improving Safety in Marine Environments:

Vulcanized Rubber Air Chambers find applications in marine engineering, where buoyancy and impact resistance are paramount. They are used in the construction of dock fenders, providing a cushioning effect between vessels and the docking structure. Furthermore, these air chambers contribute to the integrity of offshore structures, ensuring their stability even in challenging sea conditions.

Boosting Efficiency in Industrial Machinery:

Industrial machinery often operates under demanding conditions, and Vulcanized Rubber Air Chambers offer a reliable solution for optimizing performance. These chambers are utilized in equipment mounts and isolators, effectively minimizing vibrations and noise. By reducing the stress on machinery components, they enhance longevity and contribute to enhanced productivity.

Advancements and Future Possibilities:

The field of Vulcanized Rubber Air Chambers continues to evolve, with ongoing research and development aiming to unlock even more potential. Advancements in materials science and manufacturing processes allow for improved durability, performance, and customization options. Furthermore, the integration of smart technologies, such as sensors and adaptive controls, opens up new avenues for real-time monitoring and adjustments.

Questions and Answers:

Q: Are Vulcanized Rubber Air Chambers environmentally friendly?

A: Yes, Vulcanized Rubber Air Chambers are environmentally friendly. The vulcanization process ensures that the rubber is durable and long-lasting, reducing the need for frequent replacements. Moreover, the chambers can be recycled at the end of their lifespan, minimizing waste and promoting sustainability.

Q: Can Vulcanized Rubber Air Chambers be used in extreme temperatures?

A: Absolutely! Vulcanized Rubber Air Chambers exhibit excellent temperature resistance, allowing them to perform reliably in both high and low temperature environments. They can withstand extreme heat or cold without compromising their structural integrity or functionality.

Q: Are Vulcanized Rubber Air Chambers customizable?

A: Yes, Vulcanized Rubber Air Chambers can be customized to suit specific requirements. Manufacturers can adjust the size, shape, and properties of the chambers to meet the desired performance criteria. This versatility makes them adaptable to a wide range of applications across various industries.

Q: How do Vulcanized Rubber Air Chambers contribute to safety?

A: Vulcanized Rubber Air Chambers enhance safety by providing superior cushioning and shock absorption. In automotive applications, they absorb vibrations and impacts, ensuring a smooth and comfortable ride. In industries like construction and aerospace, these chambers mitigate vibrations, reducing structural stress and minimizing the risk of failure.

Vulcanized Rubber Air Chambers have revolutionized multiple industries by offering exceptional durability, versatility, and safety-enhancing features. From automotive engineering to aerospace, construction to sports equipment, the applications are vast and diverse. The integration of vulcanized rubber with air chambers provides optimal cushioning, vibration isolation, and impact resistance. As the technology continues to advance, we can expect further innovations and an even wider range of applications. With Vulcanized Rubber Air Chambers, the future looks promising for improved performance, efficiency, and safety.